If you are used to solar panels, then you may be inclined to find Printable Solar Panels a welcome innovation and the future of solar energy on many fronts.

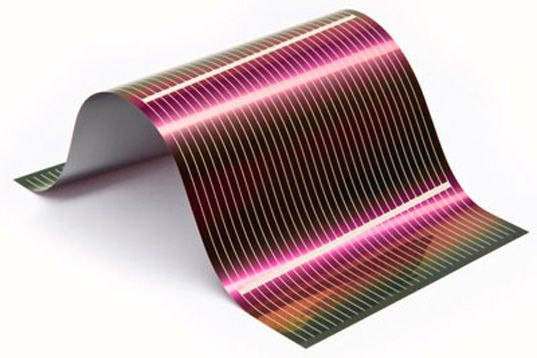

Traditional silicon-based solar panels are characterized by their bulkiness and inflexibility. Today, technology have found the need to introduce small, thin and flexible PV (photovoltaic) devices fabricated on lightweight, translucent films, which are actually solar cells produced with inkjet printing on plastic films and paper sheets.

Though, the future of solar energy definitely depends on the fusion of old, existing technology as well as newly discovered ones to arrive at an ideal safe energy to fit our time and cater to our needs.

For the purpose of this article, we will analyze what printable solar panels are, what expected benefits they offer, and challenges if any, to our environment.

What Are Printable Solar Panels?

Printable solar panels are cells that offer potentials for generating electricity more flexibly and at a lower cost, anywhere the sun shines.

They are made with a specially developed ‘solar ink’, while some contain organic semiconductors like polythiophenes that gives them the advantage to generate electricity when incorporated into windows, phones, clocks and walls.

Being typically made from many layers of material on a conductive glass or plastic substrate, each layer has a unique function. Semiconductors or sensitizers are designed to absorb visible light, while other materials will carry charge to the electrodes.

Due to its making, it is predicted that solar panels are cheaper and attain the flexibility that allows it to be installed almost anywhere.

Imagine the possibility of parts of our houses (curtains, blinds and windows) powered by solar cells. Amazing, isn’t it? In addition, some scientists believe it may even be possible to print photovoltaic elements on a wider range of surfaces – making more affordable printable solar panels, instead of costly traditional silicon panels.

Benefits of Printable Solar Cells

They help to transform the world’s energy production, reduce pollution and mitigate climate change.

It is cheaper to produce and certainly more affordable compared to the traditional silicon solar PV which is no doubt non-toxic but the silicon material is expensive to process into wafers for rooftop solar PV panels.

When photovoltaic (PV) devices that convert light into electricity is mass-produced in printing presses like newspaper and banknotes firms, they would be ubiquitous.

Challenges of Printable Panels

Flexible solar panels have few concerns, some of which are based on contaminants e.g heavy metals and hazardous solvents like (cadmium, ruthenium, and lead) used in some during manufacturing.

There is also the problem of easy degradation when not properly sealed or less efficiency at converting light into electricity.

The power generated by a PV module is directly proportional to the area which is exposed to sunlight. Annually, the world uses an estimated 20,000 terawatt hours of electricity.

Meeting this figure with PV devices will require approximately 100,000 square kilometres, and such production speed is yet to be achieved.

More precise equipment and laser processing will be required to print thin, pinhole-free layers over more than one square metre.

For these reasons, printable solar panels is yet to gain a confident place in the power market and may not become widely accepted until they are not only cheap but competent and safe to use like it silicon counterpart.

Researchers and companies must work together to improve the efficiency, environmental sustainability and stability of these cells, scale up their manufacturing and plan their market penetration.

Conclusion

The efficiency of printable solar panels or silicon panels should be accessed by their individual environmental impact of manufacture and how strike and maintain a balance.

Also, printed solar cell manufactures should find an approach that help to develop PV materials that work with existing industrial printing methods, these materials must be able to be processed into liquids, solutions, or pastes for greater efficiency.

As printable PV devices are still under development, government funding is required to support energy industries to upscale these devices from emerging status to competitive status.

Market take-on by these solar panels should be developed in stages. Like fix poor performance in low light and as complement to silicon solar cells and, ideally, be integrated into them.

Finally, printable solar panels should play an ever-increasing part in meeting growing demands for renewable energy.