This article covers coconut waste used to make pallets, the processes involved, materials required and sale.

Usually, pallets are made from woods, plastics, metals, papers, and even recycled materials.

What you may not have known is that pallets can also be made from Coconut waste too.

For starters, coconut trees do well when cultivated in nearly all kinds of soil, including salty soils found in costal areas.

It is also one of the foremost plenteous waste found in more than 90 nations of the world, with a universal generation of 62.5 million tons yearly.

You are probably wondering, how this works – making pallets from coconut waste. Well, below is how!

How to Make Pallets From Coconut Waste

The coconut waste used to make pallets are achieved through the availability and processing of certain materials.

Wherever there is abundance of coconut trees, there is cater to drinks, food and fuel.

However, coconuts waste include:

- Coconut husks

- Shell

- Pulp and

- Skin

These are all waste generated from harvesting, processing, and utilization of coconut fruit.

Though, for pallet making, only one part of coconut wate is needed which is the coconut husk.

These husks are often discarded and left to rot or burnt and when they do, they emits lots of CO2 emissions.

However, coconut husks can be pressed into any shape at a high temperature and with appropriate humidity level, the lignin will react with the fibre and stick themsl together.

To make pallets, it takes each pallet about 60 to 70 coconut husks.

Then it is left to cool down.

Note, during the making process, no glue or additives are needed, not even nails. This is because the husks contain a natural type of glue that keeps the pallet solid.

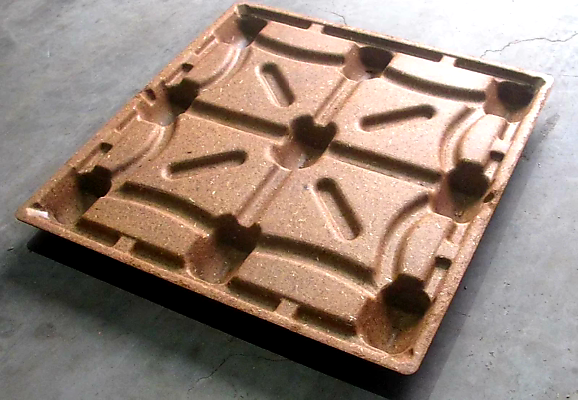

Pallets made from coconut have a nestable design, and saves up to 70% space in a traditional 40-foot container.

The pallets come standardized at 1200 x 1000 x 115mm in size, using 100% coconut husks which makes it biodegradable.

Benefits of Coconut Waste Used to make pallet

The coconut waste-made pallets prove to be beneficial in fixing several problems, such as:

- They help in reducing deforestation that wood usually be associated with wood pallets.

- They reduce waste that is generated from coconuts

- They reduce air pollution from the burning of the husks and provide the coconut farmers with extra income.

- In addition, the pallets serve as a soil-improver.

- Some places use coconut frond biomass, as a co-firing fuel for power plants.

More coconut waste is generated when there is more demand for coconut products.

Features of Coconut waste pallets

Since pallets are made out of woods, plastics etc and cocopallets have coconut husks as their main material.

They are stronger and lighter than traditional pallets, fire retardant, and are also easier to stack, so they take up less space.

As a plus, they are less expensive.”

CocoPallet have been attributed to making more durable pallets. This is because they are pest-repellent, water-resistant and biodegradable.

Also, repurposing these husks prevents them from being left to rot or burn and provide additional revenue stream for coconut farmers.

Why are coconut husks preferable to wooden shipping pallets?

Simple! Pallets that are made from coconut husks are attested to be significantly lightweighted, stronger, fire resistant and more qualitative.

They are also capable of fending off pests such as termites, unlike wood pallets that poses as a host medium for these pests. The coconut husk pallets are also more sustainable.

Conclusion

Coconut waste used to make pallet seem to be more productive and preferred by the vast majority today than the traditional wooden pallet due to the advantages it offers.

This is why, we recommend cocopallet to all interested persons, above the conventional pallets.

We trust it will prove most effective in serving and ensuring productivity during usage than wood-made pallets.